The Future of Sustainable Robotics: World's First Fully 3D-Printed Autonomous Robot Made from Recycled Materials

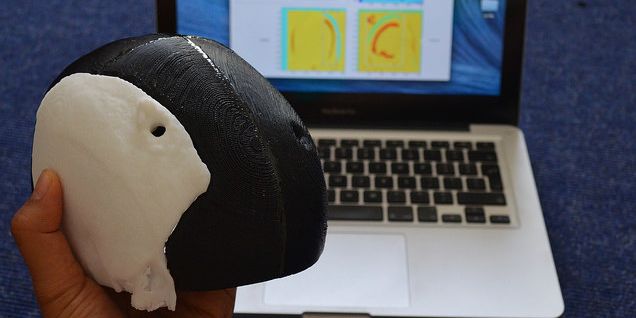

In a groundbreaking achievement for sustainable robotics, a European tech collaboration has unveiled the world's first fully 3D-printed autonomous logistics robot made entirely from recycled materials. This innovative robot, developed jointly by Lemki Robotix of Ukraine, iSCALE 3D of Germany, and Czech engineering firm Zeykan Robotics, is a significant step forward in eco-friendly engineering and decentralized production.A Leap towards Sustainable RoboticsThe robot's body, wheels, and rims are 3D-printed from recycled materials, built tough with reinforced polymers for harsh terrain. Featuring a sealed body made from glass fiber-reinforced recycled polypropylene, along with airless polyurethane wheels and carbon fiber-reinforced nylon rims, the robot is designed to operate in demanding outdoor environments. With 360° cameras, LiDAR, and Starlink satellite connectivity, the robot can be controlled manually or autonomously using an onboard neural network that processes sensor data for intelligent navigation.Designed for Demanding MissionsThe robot is designed for demanding missions such as military logistics, disaster response, and agricultural operations. Its hermetically sealed design allows it to cross shallow water bodies and operate in harsh outdoor environments. The robot's modular design and recyclable construction enable local manufacturing worldwide with consistent quality, reducing the environmental footprint and production costs.A Proof of Concept for Large-Format 3D PrintingThe robot is more than just a functional machine; it's a proof of concept for large-format 3D printing's potential to revolutionize automation and mobility. The team's innovative approach to 3D printing using recycled materials has opened up new possibilities for sustainable production and reduced waste. The collaboration between Lemki Robotix, iSCALE 3D, and Zeykan Robotics is proof of the power of teamwork and innovation. The team's dedication to sustainable robotics and 3D printing has resulted in a groundbreaking achievement that could shape the future of automation and mobility.A New Era of Sustainable ProductionThe robot's development is part of a larger trend towards sustainable production and reduced waste. The use of recycled materials in 3D printing has the potential to significantly reduce the environmental impact of production, making it a more sustainable and eco-friendly option. The team behind the robot has also developed other innovative projects, such as the Discover 3D camper, a fully 3D-printed mobile home made from recycled materials. This project showcases the team's commitment to sustainable manufacturing and innovative design. As the world moves towards a more sustainable future, innovations like this will play a crucial role in shaping the future of production and mobility.

(1).jpeg)

.jpg)

(1).jpeg)

(1).jpeg)

.jpg)