"Dream, Dream, Dream! Conduct these dreams into thoughts, and then transform them into action."

- Dr. A. P. J. Abdul Kalam

"Dream, Dream, Dream! Conduct these dreams into thoughts, and then transform them into action."

- Dr. A. P. J. Abdul Kalam

7 Mar 2024

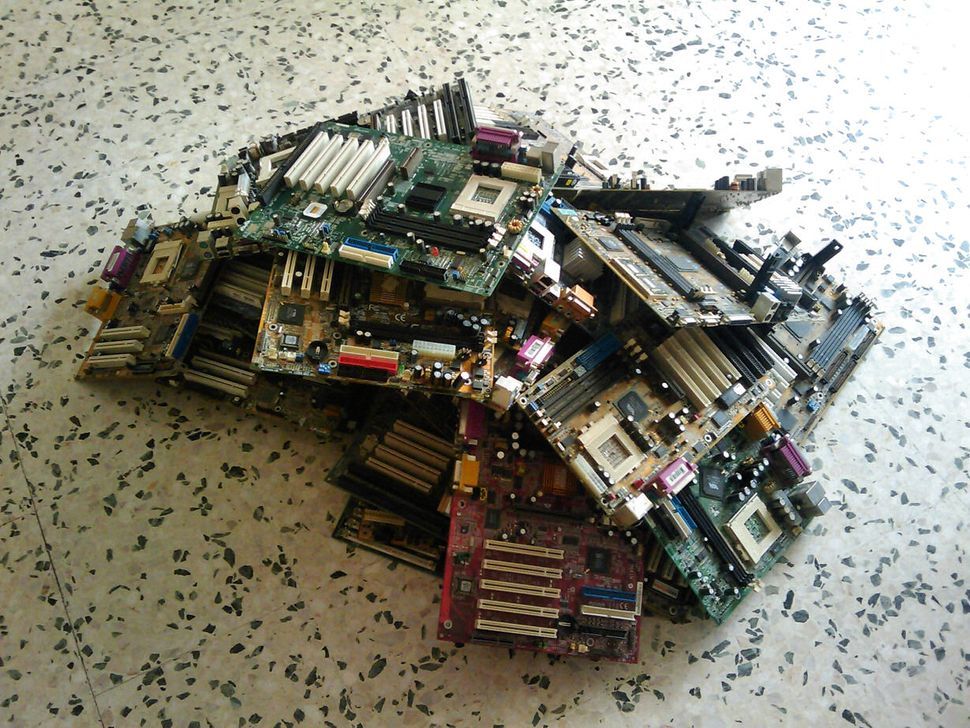

In an age where e-waste is growing as fast as our dependence on technology, a timely discovery emerges from the laboratories of ETH Zurich in Switzerland. Scientists have found a way to extract gold from the discarded circuits of our digital lives using only a by-product of cheese production - a favorite additive of bodybuilders: whey. This remarkable method not only promises a more sustainable future for e-waste recycling but also redefines the ancient alchemy of turning waste into precious metal.

Understanding the impact of e-waste ~

E-waste contains hazardous substances such as lead, mercury, cadmium, and many other toxic substances. If these substances are not properly treated, they can pollute soil, water, and air and pose a serious threat to human health and ecosystems. Sustainable electronic waste management ensures proper handling, recycling, and disposal of electronic components. Failure to do so poses a serious threat to ecosystems, wildlife, and human health.

Modern Alchemy and the Golden Sponge ~

At the heart of this process is a simple but very effective material: a protein fibril sponge made of 'whey'. Professor Raffaele Mezzenga and his team from ETH Zurich's Department of Health Sciences and Technology say that converting this e-waste into a valuable metal is very efficient, cost-effective, and last but not least ~ environmentally friendly. This is in contrast to traditional e-waste recycling, which consumes a lot of energy and often uses highly toxic chemicals to extract precious metals. Protein fibril sponges are made by denaturing whey proteins under certain conditions to form a gel of protein nanofibrils. After drying, this gel becomes a sponge capable of selectively adsorbing gold ions from a solution of dissolved electronic components. The beauty of this method is its selectivity; While other metals can adhere to the sponge, gold does so more efficiently, making the recovery process both precise and efficient. By absorbing the gold ions, the researchers apply heat to the sponge and start a reduction process that turns those ions into gold. metal flakes. Those flakes are then melted into a gold nugget. Remarkably, the team successfully created a 450-milligram 22-carat gold nugget from components of 20 old computer motherboards, proving the efficiency and scalability of the method.

Current treatment methods: 3 pillars of Sustainable E-Waste Management ~

1. Reduce

The most effective way to deal with e-waste is to minimize its generation. Encouraging consumers to buy less, use a longer-term mindset, and promote durable and repairable electronics can significantly reduce electronic waste. In addition, manufacturers should focus on ecological design and develop products that are easier to disassemble, repair, and upgrade, thereby extending their service life.

2. Reuse

Extending the life of electronic devices through reuse is a sustainable approach. Companies can create programs to recycle and recycle electronics, making them available to individuals or organizations in need. Donating or selling used equipment, ensuring proper operation and erasing data, promotes waste reduction, and facilitates access to technology for those who might not be able to afford it.

3. Recycling

Recycling is an important part of sustainable e-waste management. Creating efficient recycling systems helps collect valuable materials from end-of-life equipment and minimizes the environmental impact of raw materials. Cooperation with certified e-waste recyclers ensures the safe and responsible use of electronics following strict environmental and information security standards.

Toward a Greener Future ~

According to the World Health Organization, e-waste is the fastest-growing waste stream on the planet. In 2019 alone, a whopping 53.6 million tons of e-waste were produced worldwide, of which only a paltry 17.4% was collected and recycled. E-waste contains a cocktail of hazardous substances, including lead, mercury, and flame retardants. When these toxins are dumped in landfills or burned, they can leach into soil and water, polluting the environment and endangering human health. The impact of this new technology extends far beyond the confines of the laboratory. By offering a method that uses recycled materials and requires significantly less energy and financial investment, this new type of recycling paves the way for more sustainable practices in the gold recovery industry. In addition, it not only deals with e-waste but also gives new life to the by-products of the food industry. "What I like the most is that we use a by-product of the food industry to get gold from e-waste," Mezzenga said in a press release.

Sustainable e-waste management is important to save the environment and ensure a healthier future. By reducing, reusing, and recycling electronic devices and components, we can minimize the harmful effects of electronic waste. Through cooperation, education, technological development, and global cooperation, companies can reduce emissions and conserve natural resources.

The group's future objective is to develop and get the technology ready for market use. While there are other possible sources, the most promising starting product from which they want to extract gold is electronic trash. These are made of industrial waste from processes like producing microchips or gold plating. In addition, researchers plan to investigate the potential for creating protein fibril sponges from other food industry waste materials or byproducts that are rich in protein.

This innovation has the potential to drastically alter the way computer garbage—at least waste with significant gold content—is handled. E-waste is rapidly emerging as one of the world's largest unexplored revenue-generating sectors. E-waste entrepreneurs are already generating $85,000 a day by recycling copper and gold from electronic garbage. Over the next two decades, this business will grow significantly, and recyclers will need more effective methods for handling electronic trash. Mezzanga gives them exactly that with their sponge technology.